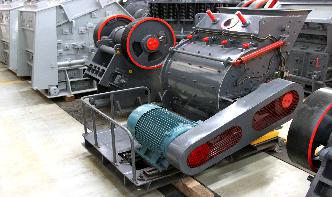

Roll Crusher | Lump Breaker | Williams Crusher

Single Roll Crushers reduce via a combination of impact, shear, and compression. The rolls are always toothed in patterns suited to the feed material. Single Roll Crushers generally handle larger feed sizes at higher reduction ratios in higher capacities and are particularly well suited to be used as lump breakers.