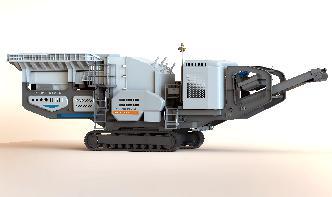

Portland cement Manufacturing process Mining Equipment

Portland cement Manufacturing process Portland cement is made by heating raw materials rich in oxides of silicon, calcium, aluminium and iron to temperatures of around 1200 – 1400oC. The chemical reactions that occur within the partially molten mass result from the formation of the four main cement .