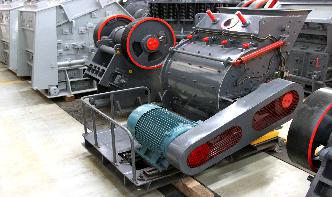

high speed feeder equipment belt conveyor for iron ores

The conveyor feeding the crushing unit at Argonaut Gold's Minera Pitalla was . Impact idlers allowed excessive belt sag, causing high volumes of spillage. An iron ore mine was experiencing premature deterioration on the wear plate of a transfer Martin Saves Cement Plant 5,000 Per Month In .