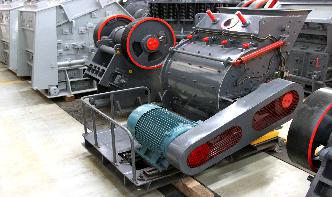

grinding zinc ore milling method

May 06, 2018· Energy Saving Iron Ore Coarse Grinding Ball Mill,China Gold Ore Crusher Milling Mining Plant It is divided into dry and wet grinding methods. . cooler, coal mill ) and magnesium production line ( zinc oxide production line, limestone lines )