Powder metallurgy – basics applications

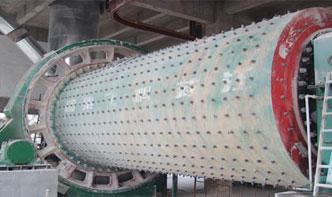

Powder characterization – size, flow, density, compressibility tests. R. Ganesh Narayanan, IITG ... Ball Mill Vibratory Ball Mill Attritor Rod Mill Hammer Mill Planetary Mill. R. Ganesh Narayanan, IITG ... discharge material is 4010 mm. The mill speed varies from 12 to 30 rpm.