091102 Iron ore Ecofys Consultancy

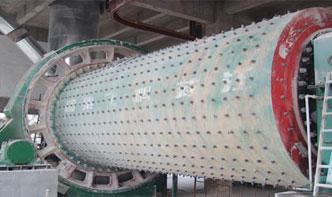

The production of iron ore pellets can be described as follows: Nonagglomerated iron ores (sinter fines) are mixed together with additives in a ratio that depends on the desired pellet quality and on the quality of the sinter fines.